At Motor Specialty, we specialize in design and creation of custom motors. One main component of a custom motor is the armature. Armatures were first utilized by magnet keepers in the 19th century.

The armature is an integral part of the motor (or generator), as this is the component that carries the alternating current (AC) in an electric machine. The armature conducts AC, even on Direct Current (DC) machines using the commutator (which reverses current direction every so often) or due to electronic commutation.

The armature also provides support and housing to the armature winding. The magnetic field in electrical machines is generated by a permanent magnet or electromagnet. The armature winding combines with the magnetic field formed in the air gap.

The function of an armature is multi-purposed. The main role is to conduct current over the field, thus generating shaft torque within an active machine. The secondary purpose of an armature is to produce Electromotive Force (EMF). Another fact about armatures is that they can be used on both stationary and rotating parts.

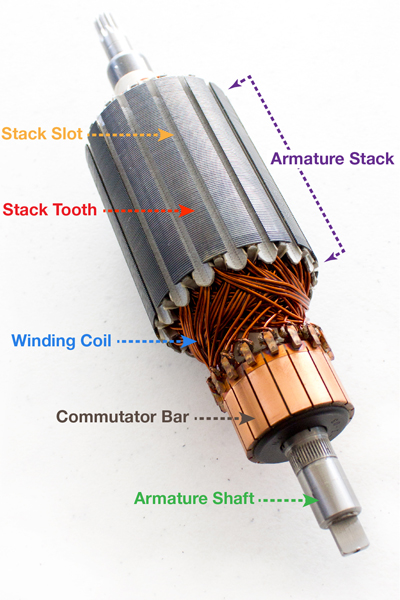

Armatures are comprised of a number of components. These parts include the core, the winding, the commutator and the shaft. Armatures can be applied in a variety of ways including:

- Electric machines for generating power

- Used as a rotor (rotating electrical component) otherwise stator (stationary electrical component), used to monitor current when used as an application for DC motors

All armatures and fields from Motor Specialty are made in the United States and are available as a set or individual components customized to your design. Please contact us today to discuss your armature and fields needs.