At Motor Specialty, we specialize in the design and creation of custom motors, which are all proudly manufactured in the USA.

One of the main components of a customized motor is the armature. This part was initially applied by magnet keepers (soft iron bars placed at either end of a pair of magnets, used to avoid the self-demagnetization of magnets) in the 19th century.

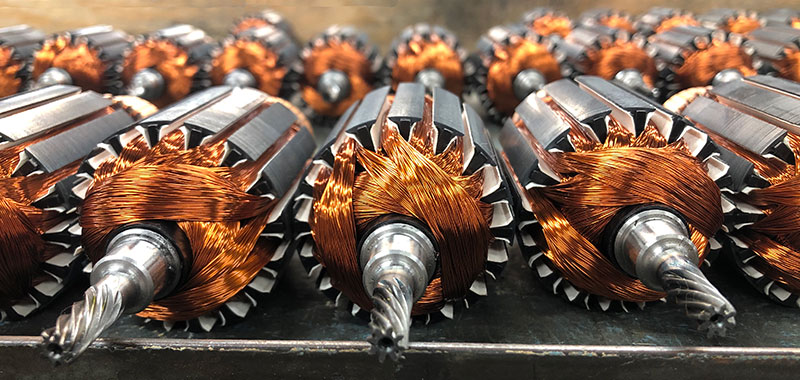

Being the component that transfers the alternating current (AC) in an electric machine, the armature is an essential part of the motor or generator. The armature is the conductor for the AC current, this includes Direct Current (DC) motors using a commutator (which periodically reverses current direction). The armature also provides support and housing to the armature winding.

Armatures include several components, which are:

- Core

- Winding

- Commutator

- Shaft

Armatures have a multi-purposed function and can be used in different applications, such as:

- Generating power

- Rotor (rotating electrical component)

- Stator (stationary electrical component)

- Monitoring current (when used as an application for DC motors)

Motor Specialty armatures can be found in a variety of electric machines:

- Pipe threaders

- Drain cleaning equipment

- Home comfort devices

- Electric hoists

- Industrial vacuums/Blowers

- Handheld disc grinders

- Industrial vacuum cleaners

- and many others

Our armatures and fields can be purchased as a set, or as individual components. They can also be customized to specific requirements, including several mounting options. At MSI thousands of armatures are made everyday, and with over 70 years of experience our team can help you get them on the market fast.

Browse our Armatures & Fields page to learn more about our specialty armatures and how we can best help you as your armature partner!