Motor Specialty Inc. has been committed to quality since our inception in 1947. In keeping with this commitment, in the early 2000s MSI invested in new windows-based testing equipment, automated balancing and upgraded several field designs to include bondable magnet wire. MSI continues to deliver quality year after year, consistently boasting a record of less than 1% in total warranty claims.

This record of excellence is not enough to satisfy MSI’s “100%—no exceptions” philosophy.

MSI is proud to announce that we will be introducing two new armature and field testers to our production line in order to streamline manufacturing processes. This investment will result in dramatic improvements both in testing speed and accuracy and will increase manufacturing efficiency by up to 40%. At a rate of 300 parts per hour, these testers have the combined capability to yield 3 times the volume of MSI’s current testers.

The first tester, model ESW AT7000, was purchased from Baldor/Reliances’ tang-wound motor plant and was developed by Electronic Systems of Wisconsin, a local Racine business–a partnership which aligns with Motor Specialty’s “buy American” philosophy. This model is capable of testing the armature of motors of 12, 16, 24 and 32 bar design. Parts are wound, fused, wedged and tested in a single use, saving employees valuable time.

“Instead of having to test and re-test parts to catch pulses (scratches), we can now test armatures in a single location,” says Charles Helm, Vice President of Manufacturing.

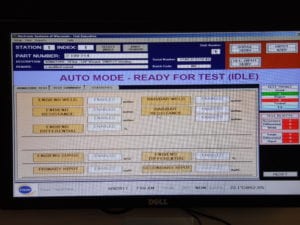

ESW AT6000-50385 Dual Station Armature Tester

The second model, an ESW AT6000-50385 Dual Station Armature Tester, was also developed by ESW—this time customized to MSI’s specifications. This tester is capable of rates of up to 300 parts per hour, increasing capacity to over 3 times the volume of MSI’s current testers. In addition, the AT6000-50385 can test on two sides at once and is equipped with different sized commutator sockets, which will save employees the time it would take to switch out commutators each time the size changes.

“It’s the Cadillac of testers,” boasts Helm.

Types of testing capabilities for the AT6000-50385 include:

- End-to-end testing

- Bar-to-bar weld testing

- Bar-to-bar resistance testing

- Surge testing

- Ground testing

According to Tim Naegeli, Vice president at ESW, the real added benefit of the AT6000-50385 lies in its computer-based data collection and analysis software, which is done through a software system called Trend Tracker.

Naegeli says this technology is “the latest and greatest on the market,” with the ability to track performance and provide statistical analysis within any given time period. This means that in the event of a warranty issue, MSI has the ability go back to any date and look at the data in order to find and correct the issue, an ability which they did not previously have.

AT6000 Dual Station Armature Tester – Main Tester Screen

“The goal for us is to never allow any bad armature to get into the final product,” says Naegeli, a goal which aligns with MSI’s commitment to quality, “which means cost savings for MSI and for the customer,” a goal which embodies MSI’s “Pride in Motion.”